In line with the UN SDG 12 on Sustainable Consumption and Production (SCP), auto manufacturer Honda has pushed on its accelerator toward circular materiality.

The company is advancing a recycling initiative that takes uniforms worn by associates and textile waste from its U.S. manufacturing and R&D facilities and transforms them into sound-absorbing insulation for use in Honda and Acura automobiles.

The initiative:

The Honda uniform recycling program leverages cross-industry collaboration between Honda and its uniform suppliers Aramark and Cintas Corporation, as well as insulation supplier UGN Automotive and textile recycler Leigh Fibers. Uniforms from Honda production and R&D facilities in Alabama, Indiana, North Carolina and Ohio are recycled and reused in five different insulator parts on all nine Honda and four Acura models made in North America. In the future, Honda plans to expand the uniform recycling program to other facilities in North America.

The process:

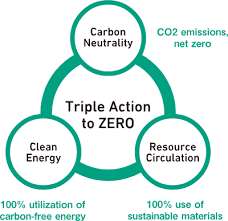

The effort is a part of Honda’s Triple Action to Zero approach which focuses on resource circulation to make new products from 100% sustainable materials toward its resource circulation goal of making new products from 100% sustainable materials by 2050, the company said in a press release.

This program diverts approximately 45,000 pounds of uniforms from reaching landfills each month. To maximize end-of-life material recycling, the uniforms are shredded into fibres and repurposed for insulation in new Honda and Acura automobiles. The program reduces waste to landfill from the company’s manufacturing and R&D facilities. More than 380,000 pounds of uniforms have been recycled since the program launched at the end of 2021, the company said.

The transformation:

Uniforms designated for reuse in Honda and Acura vehicles are baled and sent to Leigh Fibers where they are shredded into material that can be used as vehicle insulators. After extracting zippers and buttons, the material is blended and reprocessed, it is delivered to insulation supplier UGN. UGN blends, consolidates and trims the fibres into material that is moulded into insulation and returned to Honda auto manufacturing plants for new vehicle production.

Executive quotes:

Rob Long, Senior Procurement Specialist, Honda North American Indirect Procurement: “Collaborating with Honda suppliers in the uniform recycling program has brought great value to our supply chain sustainability efforts. As Honda works to advance sustainability, we appreciate our suppliers’ efforts to innovate their business operations to reduce waste and give new life to our Honda uniforms.”

Negar Gilsinger, Manager, Resource Circulation, American Honda Motor Co: “To achieve our Triple Zero goal of 100% sustainable material use, we need to take every possible opportunity to recycle materials at end of life for reuse in our products, thereby minimizing our utilization of virgin materials. By maximizing end-of-life material recycling, we are giving our uniforms a second life in Honda and Acura vehicles.”

Pranav Singh, Director, Purchasing & Packaging, UGN Automotive: “It is part of UGN’s history and culture to maximize recycled content in our parts, reduce landfill by recycling our own by-products, and promote circular, mono-material technologies that enable end-of-life vehicle recycling. Reusing Honda uniforms contributes to these efforts by increasing the amounts of recycled materials available for insulators and opens the door to other post-consumer textile waste projects.”

Background:

Honda’s uniform recycling program builds on the company’s longstanding commitment to reduce waste and incorporate higher recycled content in Honda and Acura vehicles. The initiatives include:

• Working with suppliers to transform post-industrial textile scrap, such as fibres from denim, into vehicle insulation/absorption material.

• Reusing in collaboration with UGN, approximately 2,800 tons of recycled post-industrial textile waste – equivalent to 5.6 million pairs of jeans – and 3,000 tons of post-consumer PET (polyethylene terephthalate) bottles – equivalent to 6 million water bottles for vehicle sound-absorbing insulation.

• Using soybean-based foam for vehicle headrests, recycled plastic water bottles and recycled Honda car bumpers for wheel liners, plant-based material for the seat fabric.